Why Anodise?

Protection | Precision | Performance | Promotion

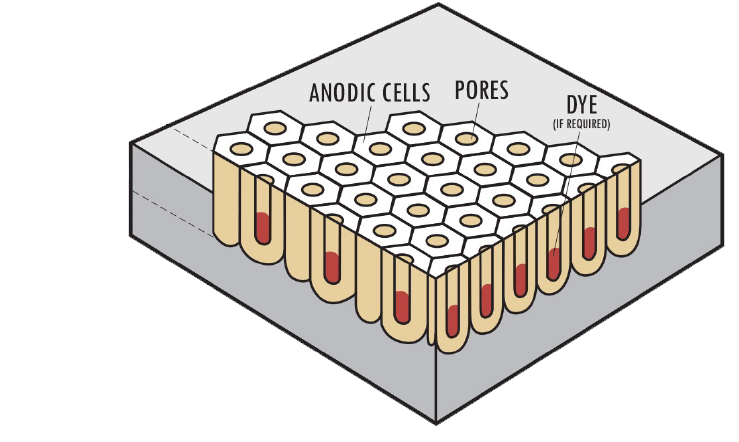

Anodising is a premium surface treatment for aluminium alloy to make it hard, durable, corrosion resistant and visually appealing.

Anodising is durable, aesthetically pleasing and easy to maintain: It directly attaches to the underlying substrate and therefore does not peel, flake or chip off like other surface treatments

Anodised parts are corrosion resistant, impervious to prolonged exposure to salt spray, most harsh chemicals, mud, oils and grease

Anodised colour is sealed into the anodic pore, remaining vibrant and visually appealing for years to come

Re-anodising extends part life: We can remove existing anodising using proprietary techniques that will leave the final finish bright and clean

All alloys can be anodised e.g., 2000, 5000, 6000 and 7000 series. Note: Ferrous metals and stainless steel cannot be anodised

We anodise parts for engineered machines, cars, boats, guns and many other creations using custom techniques, honed over many years of operation. Side-by-side, an anodised surface is the stand-out against every other applied coating.

The evidence is clear: Inside an acidic chemical bath for 5 years, the anodised part (picture, right) is barely affected. The same un-anodised part (left) was destroyed.

Why us?

We are proudly New Zealand owned and operated - Our finished products are exported all over the world. We also give your parts our personal attention: This maintains a high level of quality, and means you can move confidently to your next step. We also understand the need to keep manufacturing and assembly moving, and aim to provide the fastest turnarounds in the country.

Check out what others are saying about us on Google Reviews

“With industry-leading quality, and rapid turnarounds, our anodising protects and helps you promote your products”

— Jonathan, Lead Anodiser at Action