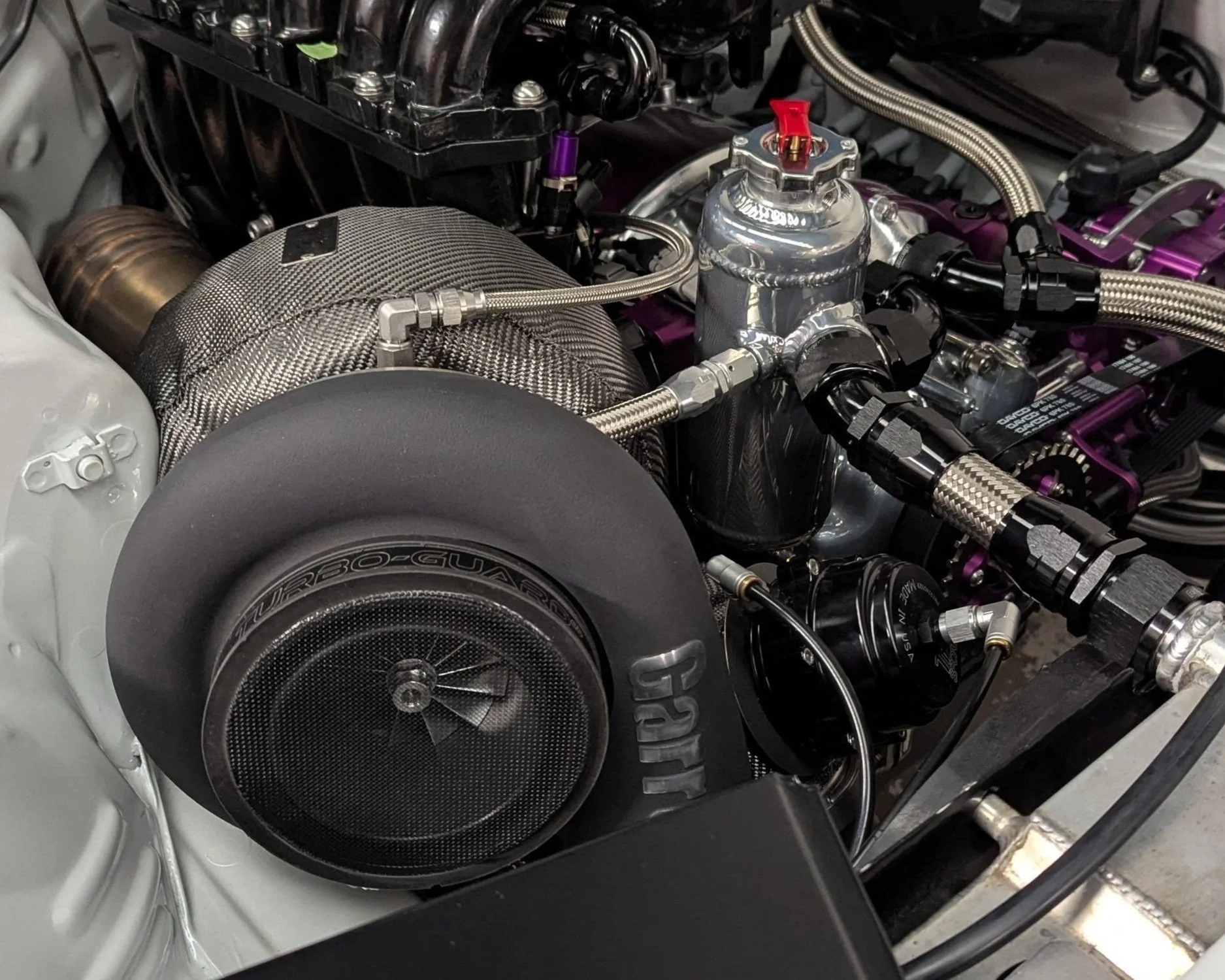

If you need an impressive finish… you’ve come to the right place.

Stand out from the crowd: Our surface coatings are highly durable and aesthetically-pleasing.

Play harder… for longer

Give yourself peace of mind knowing your anodised parts can withstand wear n’ tear and corrosion.

Whether they’re for guns, cars or boats, our anodised parts mean you can keep doin’ what you love for years to come.